- Home /

- Application /

Power engineering

Utility companies are usually divided in accordance with the type of primary product converted to electrical or thermal energy. There are three basic types of such companies:

- Thermal power plants (central heating power plants (CHPP) and state district power plants (SDPP)) operating from gas (mainly), coal or mazut;

- Nuclear power plants (NPP);

- Hydroelectric plants (HEP);

It is worth noting that gas-analysis equipment is generally used by the first two types.

At CHPP gas-analysis equipment is used for solving the following standard technological tasks:

- Continuous oxygen monitoring in exhaust gases of boilers. Data on O2 content is indicative of fuel combustion efficiency and is used for automatic monitoring of ratio of fuel and air fed to furnace. Two types of devices are used here: immersion-type oxygen analyzers with solid-state zirconium sensors and extraction oxygen analyzers with thermomagnetic sensors;

- Continuous oxygen and carbon oxide monitoring in exhaust gases of boilers. In addition to O2 monitoring, data on CO content (incomplete combustion) allows to get a broad picture of fuel combustion process and to make monitoring still more effective. Immersion-type and extraction devices are used;

- Continuous monitoring of ecological parameters (CO, NOx, SO2, dust concentration) with calculation of gross emissions on each CHPP pipe;

- Periodic adjustment of boiler operation is performed in accordance with O2, CO content (for CHPP operating from gas), and also NOx, SO2 content (for CHPP operating from coal and mazut) measured by means of specialized portable device;

- Continuous purity monitoring of oxygen (0—2 vol. % H2 in O2) and hydrogen (0—1 vol. % O2 in H2) – products of water decomposition by electrolysis method at electrolysis plant;

- Continuous purity monitoring of hydrogen used as thermal medium for turbo-generators cooling, in range 95—100 %, and also hydrogen leakage from turbo-generator cooling system (4—6 control points 0—3 vol. % hydrogen in the air for each generator);

- Continuous monitoring of oxygen content in boiler feed water (rather its absence). At CHPP special shops are organized to perform water demineralization and deaeration (removal of oxygen) before feeding to boiler so that to prevent or reduce the speed of corrosion of pipeline fittings and boilers;

- Continuous monitoring of activity of hydrogen ions (pH) and sodium ions (pNa) in boiler feed water;

And the following standard safety tasks:

- Inside electrolysis plant: continuous monitoring of excess/lack of oxygen in the air of working area; continuous monitoring of pre-explosive concentrations of hydrogen in the air of working area;

- CHPP turbine room – continuous monitoring of pre-explosive concentrations of hydrogen and maximum permissible concentrations of working area in respect of CO;

- continuous monitoring of pre-explosive concentrations of flammable gases at gas-distribution station (feeding of natural gas to CHPP) and maximum permissible concentrations of mazut vapor at backup fuel storage;

- periodic monitoring of oxygen content (up to 1 %) before boiler firing;

- periodic monitoring of maximum permissible concentrations of CO in working area and pre-explosive concentrations of flammable gases by means of portable gas analyzers, performed by care and maintenance team;

- search for leakages of natural gas and other flammable gases from fitting elements.

CHPP are charged with the task of commercial accounting of natural gas supplied to the plant. It is necessary to perform continuous monitoring of component content of natural gas and calculate its calorific content (caloric value). Collected values are examined for compliance with the parameters provided by gas suppliers and serve as an evidential basis for supervening investigation that is to follow in case the real gas parameters do not comply with the specified characteristics.

Equipment used at NPP must comply with stiff reliability and quality requirements. Each device must have corresponding certificates and permits, and each manufacturer must have a license for the right to produce equipment for NPP. FSUE SPA “Analitpribor” has all the necessary documents. Devices of versions “-A” correspond to class 3H and have seismic strength category 1.

At NPP gas-analysis equipment is used for solving the following standard tasks:

- continuous monitoring of hydrogen and oxygen content in process gas lines and in areas of reactor compartment and NPP turbine room equipped with various types of reactors;

- periodic monitoring of oxygen content in the air of working area performed with the use of individual portable devices;

- continuous monitoring of CO/CO2 in helium-nitrogen mixture bathing reactor;

- continuous monitoring of O2, CO, NOx and SO2 in exhaust gases of waste incineration plant; adjustment of operation for this plant is carried out by means of a portable device.

“Analitpribor” products used at CHPP for solving standard technological tasks:

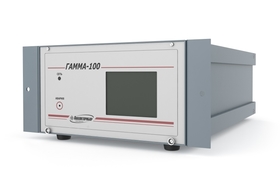

- continuous monitoring of oxygen (oxygen and CO) in exhaust gases of boilers – ГАММА-100

- continuous monitoring of ecological emissions with calculation of gross emissions – ГАММА-100

- Continuous monitoring of O2 and H2 purity – gas analyzers ДАМ with power supply units БПС-21М, or set of gas-analysis equipment (КГО) with the use of devicesГАММА-100 and sample preparation elements

“Analitpribor” products used at CHPP for solving standard safety tasks:

- Continuous monitoring of pre-explosive concentrations of flammable gases and hydrogen: for hazardous areas – gas alarms ДАТ-М with power supply units БПС-21М; for non-hazardous areas – gas alarms СТГ-3 with power supply units БПС-3

- Continuous monitoring of maximum permissible concentrations of carbon oxide in working area, and also monitoring of oxygen content: for hazardous areas – gas analyzers ДАХ-М with power supply units БПС-21М; for non-hazardous areas – gas alarms СТГ-3 with power supply units БПС-3

- Portable device for periodic monitoring of oxygen content (up to 1 %) before boiler firing – АНКАТ-7631Микро-О2-ВД

- Portable device for periodic monitoring of pre-explosive concentrations of flammable gases, maximum permissible concentrations of toxic gases and excess/lack of oxygen in working area (up to 4 gases simultaneously, in different combinations) – АНКАТ-7664Микро

- Leak detector for search of leakages of natural gas and hydrogen – ИТ-М Микро

“Analitpribor” products used for commercial accounting of natural gas:

- Stream gas chromatograph – Хромат-900

“Analitpribor” products used at NPP:

- Continuous monitoring of hydrogen and oxygen content in process gas lines and areas of reactor department and turbine room of NPP equipped with various types of reactors – ГТМ-5101М-А and ГТВ-1101М-А — for non-hazardous areas; ГТМ-5101ВЗ-А and ГТВ-1101ВЗ-А — for hazardous areas

- Continuous monitoring of CO/CO2 in helium-nitrogen mixture bathing reactor – ГАММА-100А

- Periodic monitoring of oxygen content in the air of working area – АНКАТ-7631Микро

- Continuous monitoring of O2, CO, NOx and SO2 in exhaust gases of waste incineration plant

- Set of gas-analysis equipment (КГО) with the use of ГАММА-100 and sample preparation system